- About

- Products

-

Applications

- Industrial

- Automotive

- Agriculture

- Lawn & Garden

- Ceramic

- Cold Storage

- Food Processing

- Domestic Appliances

- Cement

- Leisure & Sport

- Machine Tools

- Mineral Ore Mining

- Oil & Gas

- Packaging

- Paper & Pulp

- Pharmaceutical

- Power Plant

- Rice/Flour Mill

- Steel

- Textile

- Forestry & Wood Working

- Buildings & Construction

- Recycling

- Accessories

- Media

- Sustainability

- Careers

- Contact

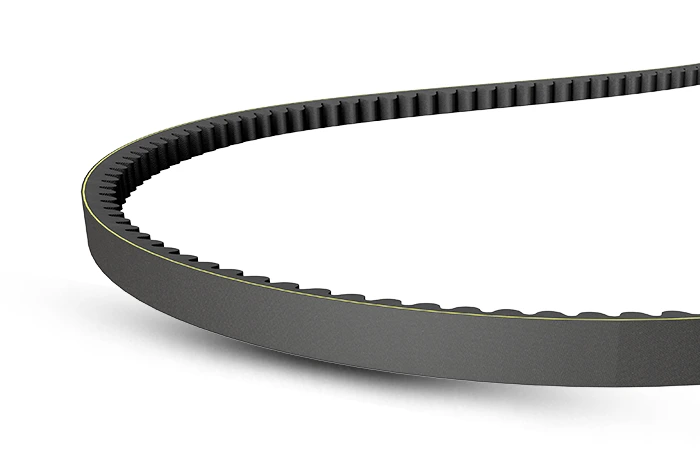

PIX Aramid Cord Belts stand as the pinnacle in the realm of industrial belts, renowned for their unparalleled strength, reliability, and versatility. Engineered with aramid fibers of exceptional durability, these belts serve as indispensable components across a spectrum of industries, offering unmatched performance in demanding environments.

Unmatched Strength and Durability

The aramid cord used in PIX belts sets a new standard for durability. Aramid fibers, known for their exceptional tensile strength and resistance to abrasion, ensure prolonged operational life, even in the most challenging conditions. This inherent toughness makes PIX Aramid Cord Belts the top choice for industries requiring reliability under extreme stress.

Applications Across Diverse Industries

PIX Aramid Cord Belts find applications across an array of industries, from automotive to heavy machinery, owing to their superior performance characteristics. These belts play a critical role in power transmission, conveying systems, and other high-load applications, where resilience and endurance are paramount.

Enhanced Efficiency and Performance

The utilization of aramid cords in PIX belts enhances operational efficiency. Their exceptional strength-to-weight ratio allows for smoother and more efficient power transmission, reducing energy losses and improving overall system performance.

Environmental Adaptability

PIX Aramid Cord Belts demonstrate remarkable resilience in diverse environments. Whether it's high-temperature environments, exposure to chemicals, or heavy-duty operations, these belts maintain their structural integrity and performance, ensuring uninterrupted operations.

Commitment to Quality and Innovation

PIX's commitment to quality and innovation shines through in their Aramid Cord Belts. Continual research and development efforts ensure that these belts meet and exceed industry standards, providing customers with reliable and cutting-edge solutions.

Product Range

| Material | Tensile strength in lb/in2 | % Elongation at break |

|---|---|---|

| Polyester | 162000 | 14 |

| Aramid | 400000 | 4 |

Aramid cord Belts are recommended, where :

- Subject to heavy shock loads

- Require superior tensile strength from the tension member

- Allow minimal scope for elongation